Excellence in precision swiss turning and milling

Located in a modern, controlled infrastructure, our company offers custom-made solutions.

Who we are

MG System is based in Ballaigues, in the area of Vallorbe in Switzerland, and has many years of experience in precision swiss turning, gear-machining and high speed milling. Our workshops are located in an ultra-modern 1500 m² factory built in 2024, in an environment with controlled temperature and humidity. All our components are 100% produced in our facilities in Switzerland.

Know-how

MG System has an ultra-modern machinery and an extensive know-how, enabling us to produce components ranging from prototypes to very large production runs, completed with a workshop focused on complete and delicate finishing.

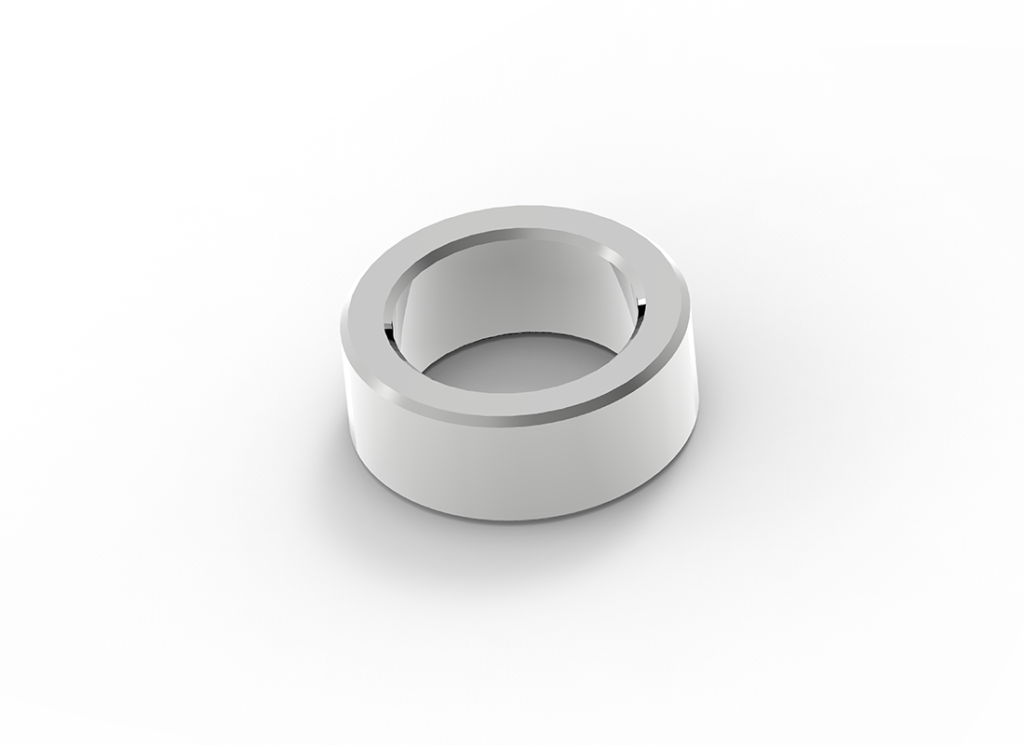

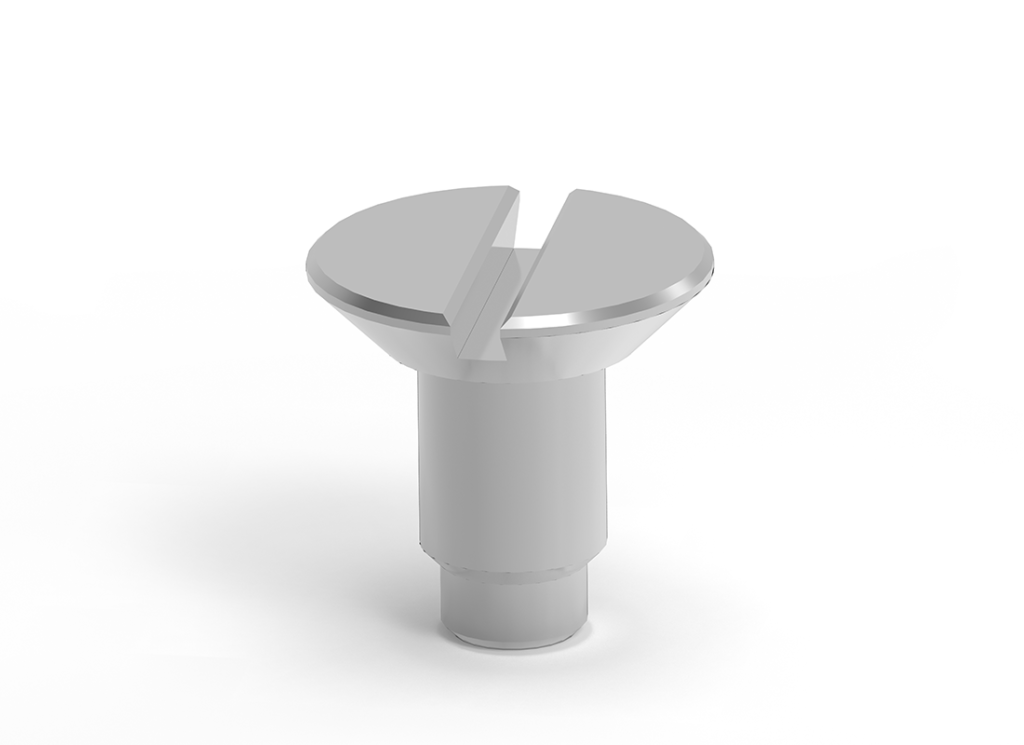

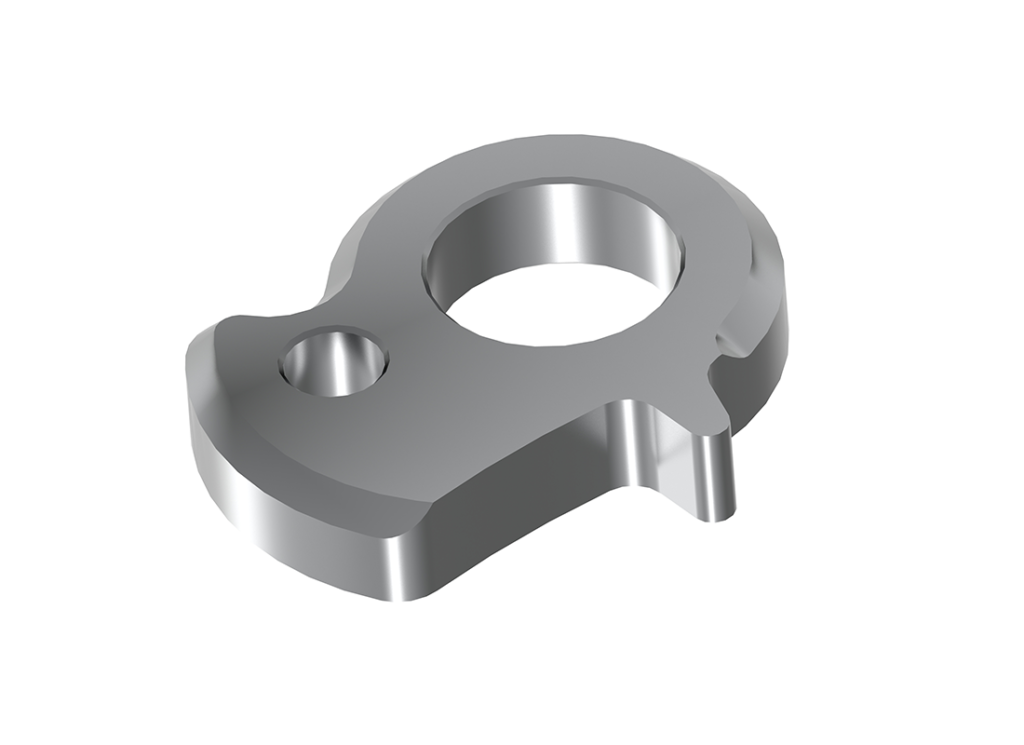

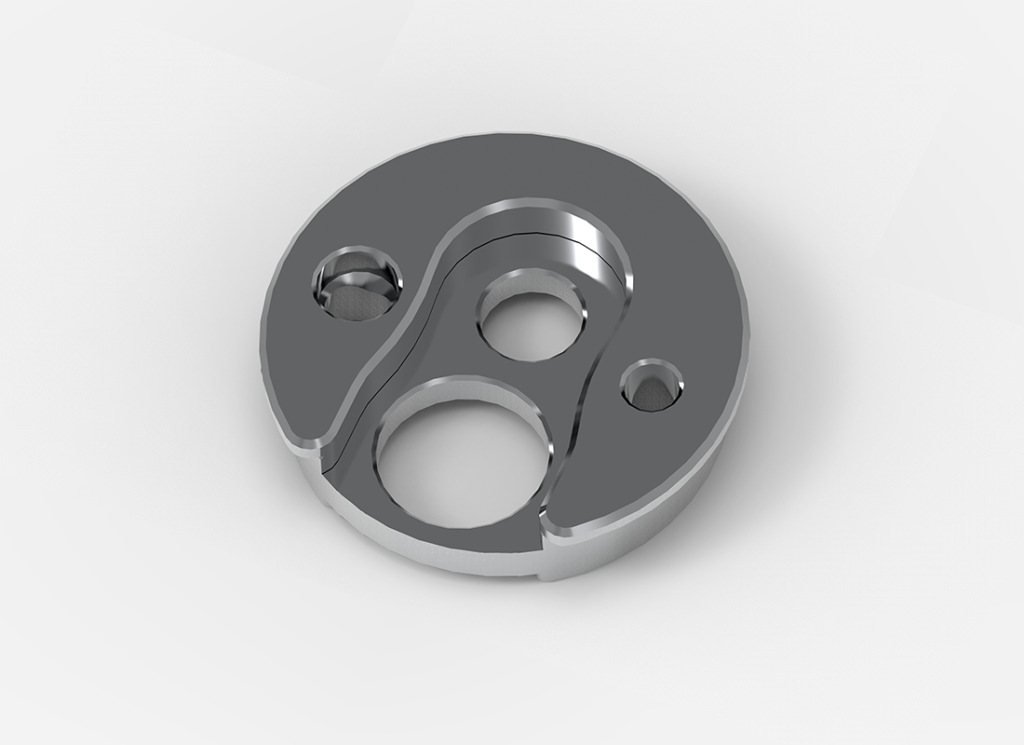

Small revolution components

Produced with or without milling, accurate to the micron thanks to state-of-the-art Citizen swiss-turning machines equipped with high-frequency milling spindles.

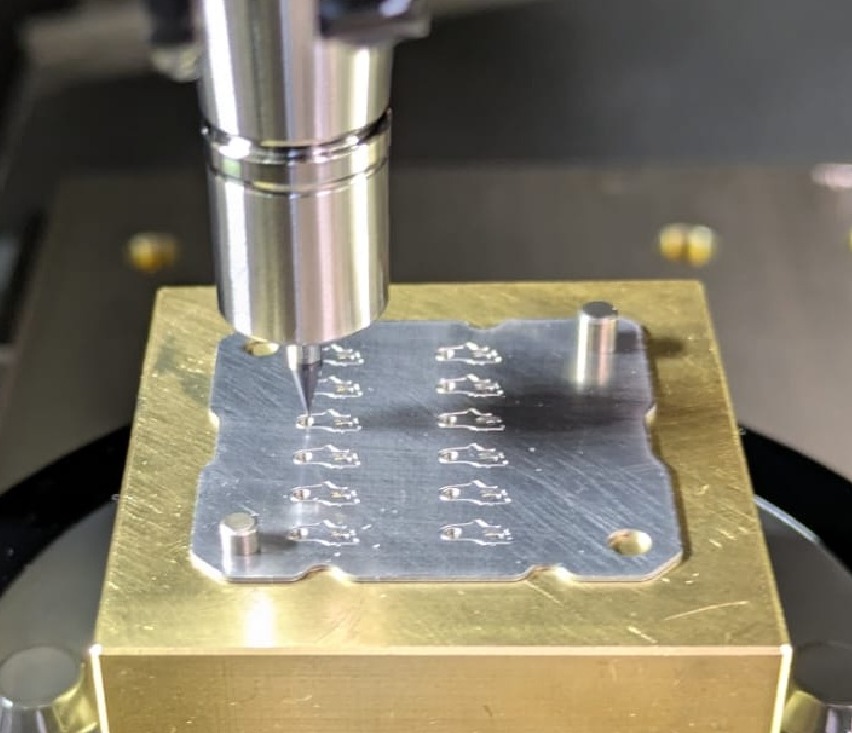

Complex steel parts

Springs and levers produced with exceptional competitiveness and repeatability. These parts are machined by plate milling on very high-precision high speed milling centers, completed with electro-erosion cutting.

Products

Watch

Movement

Arbor

Axis

Boss

Collet

Foot

Pin

Pinion

Post

Rivet

Screw

Spacer

Tube

Steel

Components

Balance bridge

Boss

Click

Corrector

Lever

Neck-chain

Pallet bridge

Ratchet wheel core

Spring

Watch

external parts

Axis

Button

Catch

Cartouche (applique)

Contact stud

Pin

Post

Screw

Tube

Jewelry

Axis

Bush

Button

Clamp

Clasp

Clip

Cufflinks

Ring

Setting

Tube

Necklace components

Wristlet components

Medical

Axis

Gear

Guide

Needle

Pin

Ring

Screw

Shaft

Tip

Tube

Components for endovascular devices

Components for pumps

Components for diagnostic equipment

Defence

Axis

Gear

Lever

Pin

Piston

Socket

Fuse components and assembly (SAD)

Materials

20AP, Finemac, 4C27A, Durimphy/Durnico®, Durimphy/Durnico

316L

Titanium

Brass, Ecobrass®, Nickel Silver

CuBe, Hardiall®, Declafor®, Pfinodal®, Toughmet®, Niclafor®,

Phynox, Nivaflex

Precious Metals

Processes

CNC swiss machining, with high-frequency milling spindles

Gear machining

Electro-erosion cutting

High-speed milling on very high-precision 3-axis centers

Heat treatment

Finishing (perlage, satin-finishing, circular-brushing)

Polishing

Assembly, manual or automated

Logistics and Quality

management

Thanks to our MRP2, quality and cyber security management systems, MG System can guarantee quality and service tailored to the most demanding requirements. Our customers come from a wide range of sectors, including:

– Watchmaking

– Medical

– Defence

– Any other industry requiring micron-level precision and reliability.

– Medical

– Defence

– Any other industry requiring micron-level precision and reliability.

Expertise and

Certification

MG System’s teams have over 20 years of experience in the manufacturing of movement and watch case components, defined by extreme precision. Our approach is also based on a strong inclination for challenge and performance.

MG System is in the process of obtaining ISO 13485 and ISO 9001 certifications, reinforcing its quality approach. We also participate in the corporate social responsibility (CSR) activities of the Group to which we belong.

Work with Us

As part of our growth and to strengthen our team, we are looking for :